|

|

|

|

Current information April 2012 Available capacities We have a possibility to take-up the production on the SKJ 8 F turning and boring lathe and underdrive PAD63A automatic press (quick punch). lathe potentials: press potentials: |

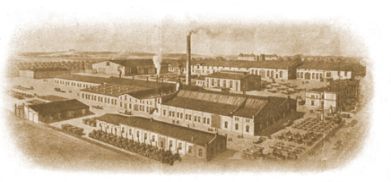

History

Since 1959 the Company which ran its business as Zakłady Sprzętu

Mechanicznego (The Works of Mechanical Equipment), started the

specialization in manufacturing of clutches, which are produced till

now, for Ursus tractors. Until 1971 the Company was an independent

entity. From January 1, 1972 it was incorporated into the structure of

Zrzeszenie Przemysłu Ciągnikowego "Ursus" ("Ursus" Tractors Industry

Association).  |

|

|