|

|

We

would like to kindly inform that we made a decision of the heretofore

manufactured spare parts to started up with sales under our own brand.

|

Current information

April 2012

Available capacities

We have a possibility to take-up the production on the SKJ

8 F turning and boring lathe and underdrive PAD63A automatic press

(quick punch).

lathe potentials:

max fi 800x200mm

press potentials:

max tonnage 63T,

strokes per minute 100-320

|

|

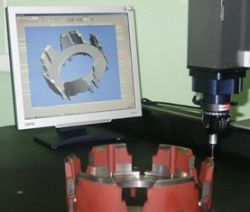

Quality Assurance Department

All

the manufacturing processes are subjected to Quality Control starting

from raw material entering the company until the finished good is

leaving the factory with the subsequent monitoring at recipient's home.

Taking such actions is result of records of ISO 9001:2000

procedures and quality plans in which following is discussed:

1. controls and acceptance testing of supplies,

2. controls and testing during production,

3. final controls and testing.

Control examinations are conducted by specially prepared

for this Quality Assurance Department personnel, equipped with

universal measuring instruments and special test equipment.

Supervision over control-measuring instruments and very

exact measurements based on basic pattern is conducted by Length and

Angle Laboratory equipped among others with measuring machine AXIOM TOO

from ABERLINK.

Chemical

laboratory: it supervises the course of chemical treatment and makes

analyses of chemical composition of the delivered materials to be used

for production.

Quality controls are used to ensure the realization of

quality requirements and documenting quality activities. On all stages

of production the documentation is kept.

|

|